In chemical industries we all need to design a pipe distributor for liquid. These distributors we generally use to distribute the liquid inside a absorber column, distillation column or a extraction column. To achieve best performance of above unit operations distribution of the liquid is most critical. A properly designed liquid distributor ensure the uniform spread of liquid across the cross section of the column and provide highest interface area between the phases.

A poorly designed feed pipe distributor can cause back flow. This we can see in case of low pressure drop across the distributor holes. While, in case of high pressure across the distributor holes causes jet & mist formation, which may lead to emulsion formation in case of liquid liquid extraction column.

Liquid Pipe Distributor Sizing

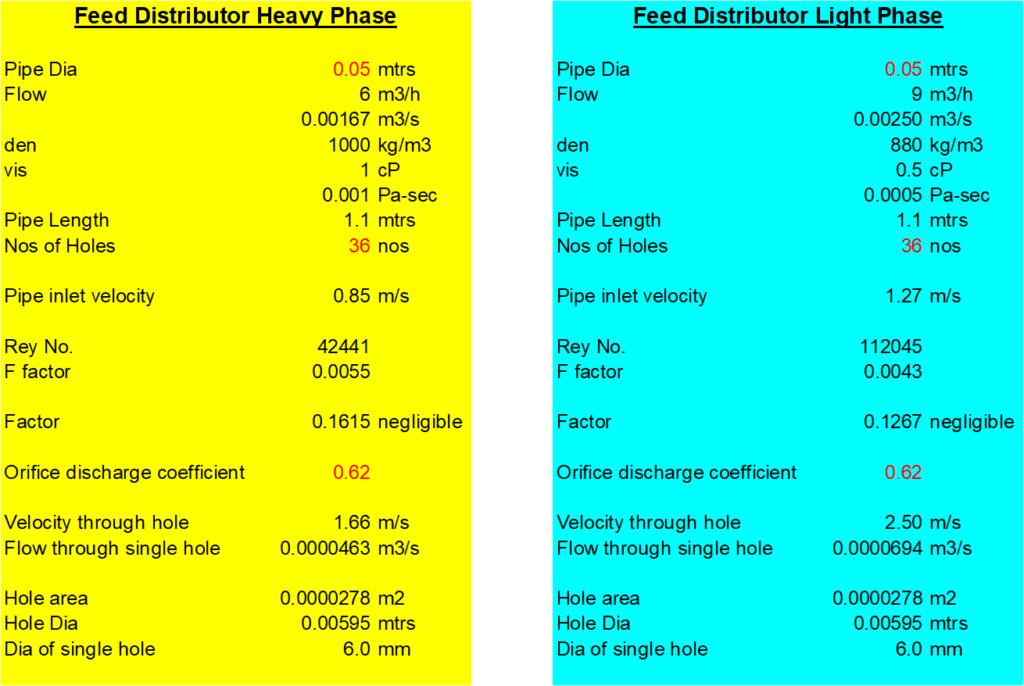

Below is the sample calculation to size the pipe distributors for a liquid-liquid extraction column:

Conclusion

Above calculation is helpful to size a pipe distributor for a given liquid feed. A properly designed distributor is very critical for the best performance of the absorber column, extraction column or distillation column.

Thanks.