In our industries we can find the use of Liquid Jet Pumps in applications such as pumping and mixing of the fluids. These industries can be related with chemical, food or pharmaceutical area. We know Liquid Jet Pumps, as Jet Ejectors or Jet Eductors also. This device uses high pressure liquid as a motive force to pump, mix or dilute a secondary liquid. This way we can eliminate the need for mechanical dosing pumps and mixers or agitators.

There are many advantages in using a liquid jet pump for certain applications, where fluid viscosity is low, fluid is not highly volatile, not very erosive in nature, has no sticky or polymerizing tendency, etc. The benefits of liquid jet pump use in such applications can be like, no moving parts, in line mixing, no or low maintenance and comparatively simple system.

Table of Contents

Principle of Liquid Jet Pump

In operation a high velocity jet of pressurised liquid discharged from the motive nozzle produces a region of low pressure in the suction chamber that entrains the secondary liquid or fluidised solid. The two streams then thoroughly mix in the throat before the resulting mixture flows through the diverging cone to regain some pressure to overcome system discharge heads.

Liquid jet pumps, utilize the pressure energy of a high-pressure fluid stream to boost the pressure and/or flow of a low-pressure fluid stream.

Ejectors are generally inefficient devices. However, their simplicity and lack of moving parts make them worthy of consideration, particularly where a high-pressure fluid stream is already available. This way we can use the available waste energy and can save energy cost for the process.

Performance of the Liquid Jet Pump

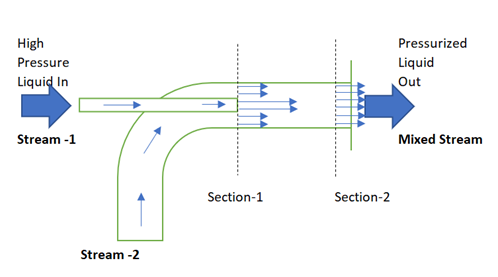

Let us refer the below simple liquid-liquid jet pump sketch.

Let us assume at Section-1, two fluids are mixing Stream-1 having mass flow rate W1 (kg/s) and Stream-2 with mass flow rate W2 (kg/s). The flow area for Stream-1, for Stream-2 is S2 (m2) and at Section-2 flow area is S3 (m2).

Mass Balance for the System

Here we can write the mass balance at steady state between Section-1 and Section-2,

W1 + W2 = W3 (here W3 (kg/s) is the mass flow rate at Section-2)

ρ1*V1*S1 + ρ2*V2*S2 = ρ3*V3*S3 -Eq.1 (i.e., rate of mass in at Section-1 = rate of mass out at Section-2)

since this is a liquid and can be assumed as an incompressible fluid hence, ρ1= ρ2= ρ3= ρ

Also, from geometry we can have, S1 + S2 = S3 -Eq-2

Therefore, we can rewrite above Eq.1 with the help of Eq.2 and above assumptions:

V1*S1 + V2*S2 = V3*(S1 + S2)

(S2/S1) = [(V1 -V3)/(V3 – V2)] -Eq.3

Momentum Balance for the System

Assuming negligible friction, the momentum balance can be written as below:

Rate of momentum in – Rate of momentum out = 0 (for steady state flow)

W1*V1 + W2*V2 – W3*V3 + P1*S1 + P2*S2 – P3*S3 = 0

We can solve the above equation for discharge pressure,

P3 = (W1*V1 + W2*V2 – W3*V3 + P1*S1 + P2*S2)/S3 -Eq.4

Hence, using above equations we can estimate the inlet pressure and flow rates to meet the required discharge flow rate and pressure requirements.

Various Applications of Liquid Jet Pump

We can find various industrial application of Liquid Jet Pumps as below:

- Eductors Inside as Storage Tank for mixing the liquid inside. In many cases such as dilution of incoming feed into the tank or when there are multiple streams are coming into the tank with different composition. In such cases Eductors can be very helpful and below figure shows the typical installation.

Here, the pump provides high pressure liquid stream which passes through the jet pump or eductor nozzle and pumps the tank liquid to make it a homogeneous mixture. This way we can avoid the installation of large size agitators and motor power consumption.

- Second application we can see for inline dilution of some concentrated solution. Many times, we use dilute NaOH solution for our process requirements and available is of 48% concentration. So, in such cases we can use an inline liquid-liquid ejector to get the desired dilute caustic solution. The typical installation in such cases can be as shown in below figure.

So, this way we can avoid a mixing vessel and can get continuous feed of dilute caustic solution.

- Another use we can see to pump the liquid using available high-pressure liquid. This way we can use available waste energy and can save power bill for the process. This type of arrangement we can understand by below figure.

As we can see in above figure, the primary fluid is passed through a nozzle where the pressure energy is converted into kinetic energy. The high-velocity jet entrains the secondary fluid. The two streams mix in the mixing tube, leading to pressure recovery. Further static pressure is recovered in a narrow-angle diffuser downstream of the mixing tube.

- High pressure liquid jet generates a vacuum, which we can use to diffuse the gas into the mixing chamber. As the gas/liquid mixture enters the diffuser, the static pressure begins to recover. This way gas is compressed as it approaches into the discharge. This way, we can see the Liquid Ejector works as an evacuator as well as a compressor also.

Conclusion

Liquid Jet Pumps/Ejectors are available in stainless steel, carbon steel, duplex steel, Hastelloy, titanium, rubber lined, PP, PTFE and PVDF. Liquid jet ejectors are jet pumps, which uses high pressure liquid as motive fluid. They use the kinetic energy of the pressurized liquid to entrain liquid, gases or vapours. Moreover, these can be used for pumping slurries and other liquids or granular solids. These devices discharge the resultant mixture against a higher pressure.

We should look into the plant and should find the applications of liquid jet pumps. As this will save the power bill required for pumping or generating vacuum. Also, this is the idea of creating wealth from waste energy, where we have high pressure liquid stream available.

Thanks for reading..