The centrifugal pump process data sheet (PDS) is the part of Basic Engineering package. This document is required to float the inquires to vendors. After, receipt of offers from pump supplier we prepare technical bid evaluation (TBA). In this TBA process engineer give his recommendations from process point of view for different vendors. Which purchase manager considers during the order finalization. Hereafter, this TBA is handed over to procurement department to negotiate and place the order for purchase.

Therefore, process data sheet is a very important document for the right selection of the pump for our requirement. Every process engineer should understand the pump specifications data sheet thoroughly, so that pump selection is appropriate. For the preparation of pump process data sheet, you can consider following point.

Capacity & Head

This is important parameter for any pump because this will decide the performance of your process. If you mention wrong capacity & head, you will not be able to run the plant. So, it is necessary to estimate the normal operating parameters for the pump. You should estimate the head loss in pipeline and fittings correctly. Add the static head (i.e., vertical height difference between pump level and discharge level) and discharge operating pressure to get total required head for the pump. Based on your process requirement you should mention minimum and maximum capacity and head requirement, this will help vendor to select the best efficient pump for your service.

Service Fluid & It’s Properties

For pump selection service fluid and its properties are very critical. Corrosive fluids require material of construction such as SS316L, Hastelloy, PTFE lined, rubber lined, PVDF etc. For viscous fluids we use different types of pumps such as gear pump of screw pump. Solid content in the fluid is important for MOC (Material of Construction) and pump mechanical seal selection. Therefore, following information must be there in centrifugal pump process data sheet.

- Fluid composition

- Density (min/normal/max) – based on the temperature variation of pump

- Viscosity (min/normal/max)

- Fluid nature (corrosive/erosive)

- Solid content (in %)

- Vapor pressure

Net Positive Suction Head (NPSH)

The pressure at pump suction must exceed the fluid vapor pressure by a certain value to avoid cavitation. This value is called net positive suction head or NPSH. Pump cavitation causes fluctuation in flow and create abnormal sound in pump. Because of cavitation pump can stop pumping and moreover damage pump impeller also.

For pumps there are two types of NPSH as below.

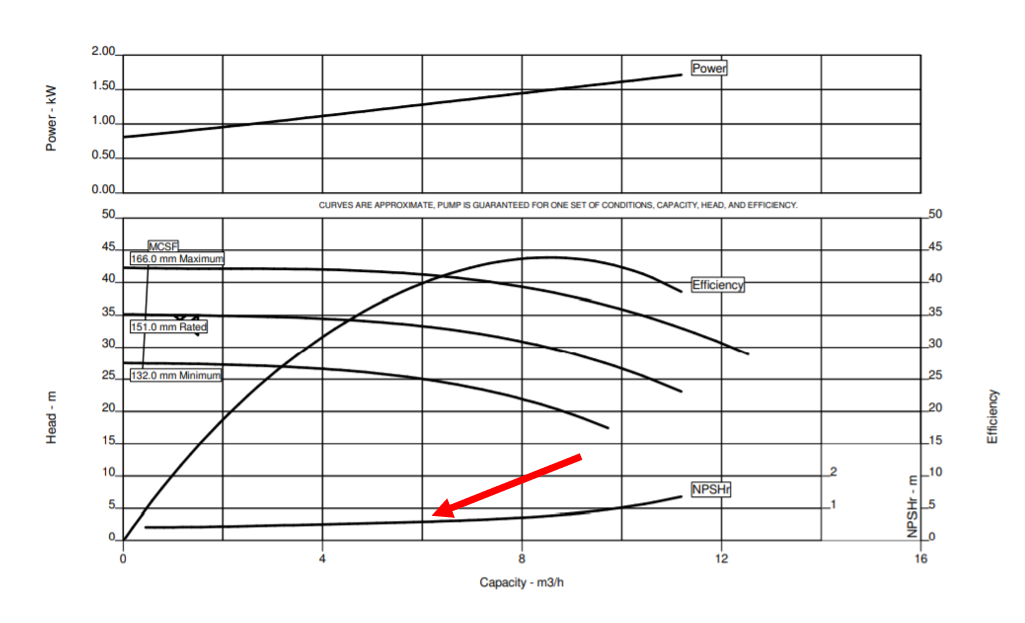

NPSH Required – This parameter depends on pump model and given by the pump manufacturer. The NPSHR is about 2 to 3 meters for small pumps and increases with capacity, RPM and discharge pressure. In below pump model characteristic curve, we can see at the end of curve NPSH required is highest and capacity, head, efficiency are lowest. For below pump model at 6 m3/h and 25 meters head, NPSH required is around 3 meters. So, to avoid cavitation in this pump you require a pressure higher than 3 meters at the inlet.

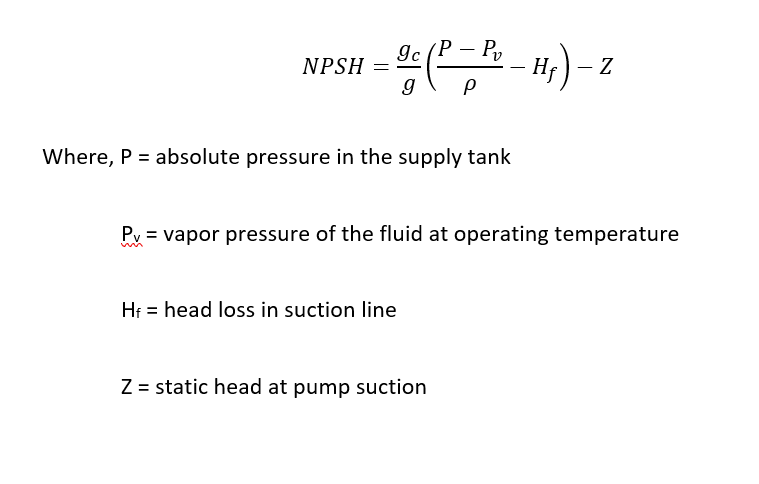

NPSH Available – A process engineer need to calculate the available NPSH. So that pump manufacturer can select a suitable pump model for our service. The NPSHA depends on fluid vapor pressure, head loss in suction piping and static head at pump inlet. You can calculate the NPSHA for a using below equation.

Pump Engineering Data

This section of data sheet includes the information which are important for the mechanical design of the pump. Important engineering data are as below.

- Design pressure and temperature

- Installation conditions of the pump (indoor/outdoor)

- Pump RPM (commonly used 2900 or 1450 RPM)

- Pump mounting (Horizontal/Vertical)

- Seal type (mechanical/gland pack)

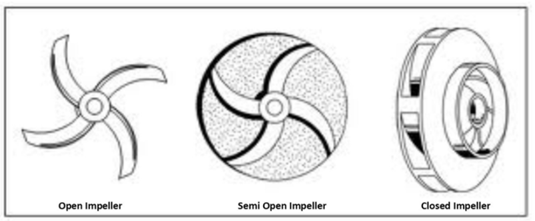

- Impeller type (open/semi-open/close) – depending on the fluid process engineer can decide the type of impeller. For chocking tendencies go for open or semi-open impellers and in clean service close impeller is efficient. However, pump efficiency depends on impeller type it is lowest for open impeller and highest for close impellers.

Pump Drive Data

Here we provide the data related to available electric power supply and motor specification. Power supply data includes voltage, frequency, supply phase. Motor data comprises RPM, flame proof of non-flame proof, mounting information, motor starter type (DOL or SD), etc. Motor installation details includes outdoor/indoor, protection class (i.e., IP class), hazard area classification, motor make (ie., Crompton, Bharat Bijli).

Pump MOC Data

In this we provide all the information related to material of construction (MOC) of the pump and it’s accessories. Pump accessories includes base frame, coupling, mechanical seal, coupling guard, foundation bolts, etc.

We can provide seal face combination details for our process requirement. For this purpose you can take help of seal experts also. Various seal face combination can be such as SIC vs C, SIC vs SCI, C vs C (SIC stand for silicon carbide and C stand for Carbon).

Seal flushing plan is suggested by the pump or seal supplier. Seal flushing plan is important for the long operating life for the seal. In the absence of the appropriate seal flushing plan seal may overheat or erode by solids. Therefore, to avoid the pump maintenance cost suitable seal flushing plan must be in place.

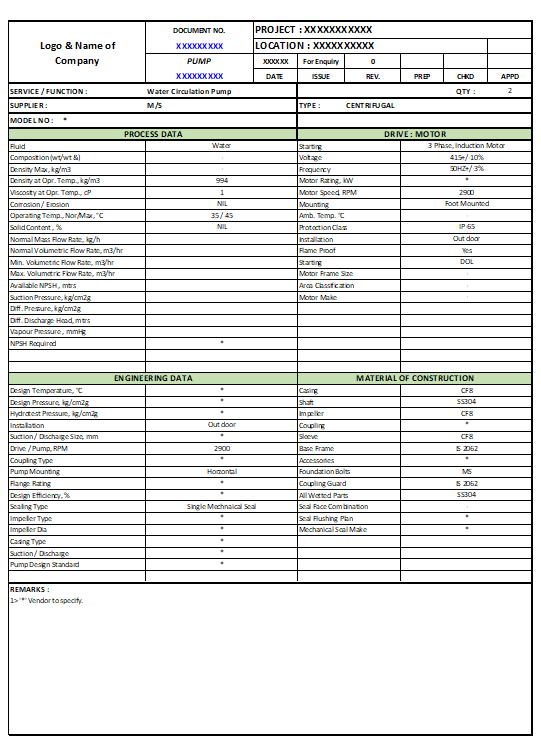

Format of Data Sheet

You can refer below format for the centrifugal pumps process data sheet. After preparation you can send the inquiries to vendors like Microfinish, Flowserve, KSB etc.

To download the Centrifugal Pump Process Data Sheet please go through below link: Click Here

Conclusion

For a good process engineer you must understand the process requirement thoroughly. So that you can prepare centrifugal pump specification sheet accurately. Moreover, you require process material balance and pressure drop calculations. In addition to that you need details of fluid physical and chemical properties. Also, pump operation knowledge is important for an efficient pump selection.

Thanks,